MACHINING & FABRICATION

From Concept to Creation with Precision

Key Services We Offer

High-Tolerance Machining & Metals Fabrication

Our engineers and technicians produce mission-critical components using advanced CNC machining, turning, and welding techniques, delivering parts that meet the demanding tolerances of aerospace, defense, and scientific platforms.

Electronics Fabrication & Assembly

We deliver full lifecycle support for electronic systems—from design and prototyping to board population, test, and integration—ensuring reliable performance for everything from laboratory instruments to flight-qualified hardware.

Composite Component Fabrication

We develop and manufacture aerospace-grade composites, including lightweight structures and test articles, using proven layup, curing, and finishing processes tailored for high-performance missions.

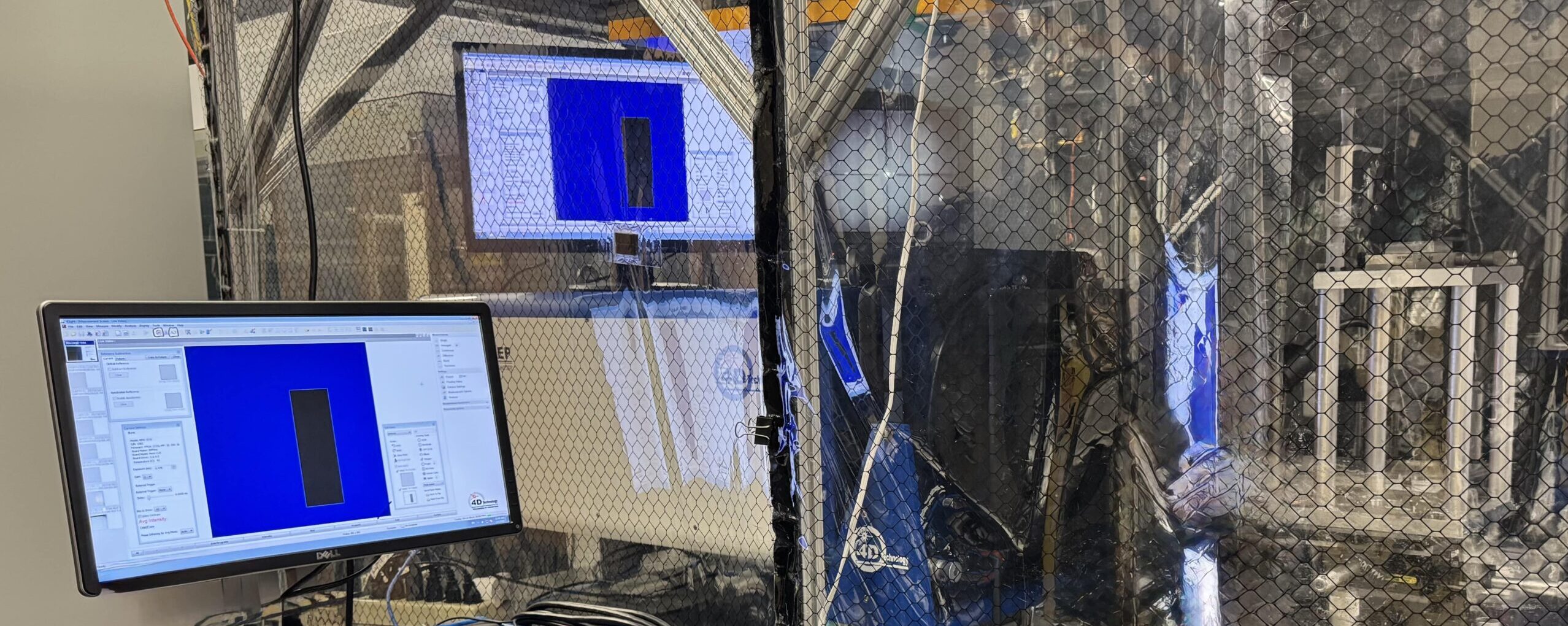

Optical Component Manufacturing

We specialize in fabrication of high-precision silicon mirrors and other optical assemblies, using advanced lapping, polishing, and metrology techniques to achieve performance standards required by leading science missions.

System Integration & Quality Assurance

We provide end-to-end assembly, integration, and verification of mechanical, electronic, and composite subsystems—supported by rigorous inspection, documentation, and test processes to ensure mission readiness.

Key Projects and Initiatives

X‑Ray Mirror Production for Space Science

We engineer and fabricate silicon mirrors for astrophysics missions, including design, lapping, polishing, and high-resolution metrology measurements. Enhanced by upgraded controls, precision tooling, and automated thermal processing, our approach delivers repeatability, throughput, and optical performance that exceed mission standards.

Mission‑Certified Hardware & Custom Electronics

Our team fabricates and tests aerospace components to meet stringent flight and space standards, while also designing and assembling advanced electronics—from prototype boards to fully integrated systems for research and defense missions.

Military Fabrication & Test Support

We provide rapid machining, welding, fabrication, and finishing services to support military vehicle and equipment testing. Our team delivers everything from custom components to large-scale assemblies, including surface preparation and specialized coatings. By integrating fabrication with on-site test support, we help shorten development cycles, ensure equipment reliability under field conditions, and accelerate readiness for operational deployment.

Why Choose STC?

Precision Manufacturing

We provide high-accuracy machining and fabrication services to support aerospace, defense, and scientific missions.

Advanced Capabilities

Our facilities deliver custom components using state-of-the-art CNC machining, additive manufacturing, and fabrication techniques.

Reliable Quality

STC is committed to stringent quality assurance standards to meet mission-critical tolerances and specifications.

Integrated Support

We work closely with engineers and program teams to deliver prototypes, flight hardware, and production-ready components on schedule.

Ready to Learn More?

When precision matters, STC’s machining and fabrication team delivers components built to exacting specifications. We provide end-to-end support for prototypes, flight hardware, and production parts. Contact us today to learn how our manufacturing expertise can power your mission’s success.